PlantStream Blog

PlantStream vs traditional 3D CAD: What’s the difference?

Date :Jul 1, 2022

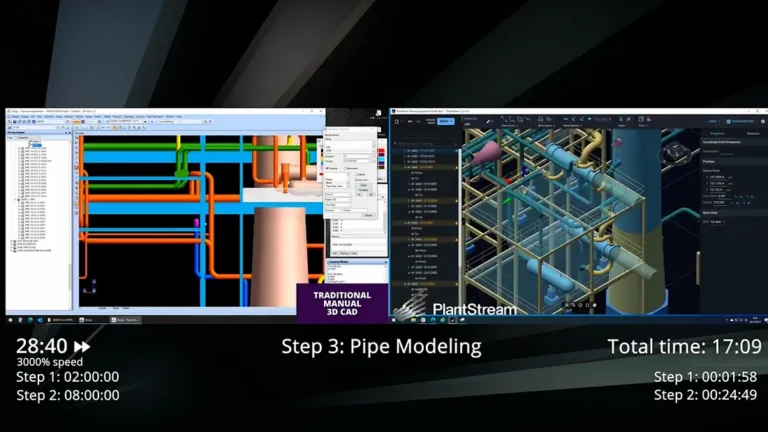

PlantStream vs Traditional 3D CAD — From Plot Plan to Pipe Modeling

https://www.youtube.com/watch?v=Ury0Wg_NAGk&t

This is true for the oil and gas industry too. As the war between Russia and Ukraine continues, supply chains in the industry remain disrupted, and major companies — like Shell and BP — have to figure out ways to reduce their overhead costs to stay afloat.

Digital technologies like 3D computer-aided design (CAD) can be a price-friendly and flexible way for oil and gas companies to innovate and stay relevant in the industry. But, which CAD software to choose? Here we take a look at what CAD is, and how PlantStream’s 3D CAD technology sets the business apart from competitors when it comes to the needs of the oil and gas industry.

Traditional CAD vs autonomous 3D CAD: How PlantStream is different

Over time, different variations of CAD have emerged. In the 1990s, only a few companies like IBM and Microsoft developed CAD software, and it was largely based on the projection of designs on a 2D plane in a sort of wireframe model. The result was somewhat ambiguous, as it wasn’t easy to tell which part of the model was in front of other parts. Designers would still have to use their imagination to see the final product, leaving room for error.

But CAD has evolved into 3D spaces, which allows a designer to see whether any point in the space is an inner boundary or external to the model. Traditional CAD software allows users to render 3D geometrical projections, which look like solid shapes, and can help designers see the depths, curves, and edges of a sketch more clearly⁴.

Autonomous 3D CAD is even more advanced than these innovations. In the design process, it might be difficult for the drafter to overcome the geometric constraints of elements that intersect, protrude, or revolve⁵. Autonomous CAD uses machine learning — where the computer is constantly learning what the designer’s intentions are and creating algorithms and data — to automatically draw new elements of a design with more speed and precision. This capability makes for a much quicker and smoother design process, as artificial intelligence (AI) makes the computer even smarter at guessing the best next step⁶.

After decades of development, there are now plenty of 3D CAD options out there. PlantStream’s 3D autonomous CAD is intended to completely optimize the process before the elimination, procurement, and construction phase of building a pipeline. PlantStream is also incredibly user-friendly. The software uses drag-and-drop features that make it easier to develop a highly sophisticated design. The software not only incorporates AI, but also teaches the user how to build a model more effectively, by having pop-ups that explain errors. And at the same time, the software boasts incredible speed. It can automatically route 1,000 pipes in a minute⁷.

The changing landscape of the oil and gas industry

The oil and gas industry will always be a major component of any advanced economy. Some estimates show the 2021 global market size of oil and gas production was $2.2 trillion⁸, and it’s expected to increase by nearly 10% in 2022.

However, the oil and gas industry is still gaining less revenue now overall. In fact between mid-2014 and early 2016 , the global economy saw one of the largest oil price declines in modern history — a drop of about 70%⁹. While the market has recovered some, there are still major political and social factors impacting the stability of the industry.

Oil and gas companies are also being asked to revise their traditional business models, as nations place greater emphasis on environmental regulations. Rules around greenhouse gas emissions have forced companies to change their energy mixes substantially, requiring them to modernize existing technology while also investing in new areas, such as solar and wind power infrastructure.

Utilities now must consider ways to innovate in order to save costs — and digital tools like 3D autonomous CAD have a significant role to play. PlantStream’s CAD software is a user-friendly, quick, and precise digital tool that designers can use to help utilities save money.

Cost overruns and schedule delays occur frequently around the world, as project cost estimates are delivered inaccurate or too late. PlantStream allows engineers to get highly accurate cost estimates from 3D models no matter the size of the pipes from exportable MTO data. Its precision and speed greatly aid the design process, and prevent cost overruns and schedule delays. By modeling thousands of pipes in just minutes, companies are able to reduce the time they need to plan and construct infrastructure, avoid expensive construction errors, and eliminate unnecessary payroll expenditures around a design team.

PlantStream success stories

Autonomous 3D CAD has already revolutionized many businesses — like in the aerospace industry. And PlantStream has already seen success with its autonomous CAD tool. For example, one of PlantStream’s earliest adopters is Chiyoda Corporation. Chiyoda was able to test out PlantStream’s software while development and troubleshooting were taking place¹⁰.

The company was hoping to use PlantStream in order to optimize its initial design phase, by using the software’s 3D models to solidify the structure of the pipe racks earlier on in the project. According to the design team at Chiyoda, PlantStream’s software offered solutions to some of the issues that were holding them back in the design and construction process. Specifically, they were able to get better feedback from their clients. The 2D models they were relying on before were too vague. The 3D models allowed the client to offer more precise feedback earlier on in the design stage, and Chiyoda is excited about the possibilities of optimizing this process¹¹.

Future of the industry

Innovation is critical for all businesses to stay relevant. Oil and gas companies are focused on delivering reliable power. And to do that, they must reconsider how to update their infrastructure, management styles, and products. Between the growing calls to decarbonize and making the necessary regulatory changes, today’s utilities must consider using advanced technologies like AI and CAD to add value to their business models¹².

CAD has been around for several decades, but it’s evolved into an incredibly advanced tool that companies can use to cut costs, save time, and maximize their workflow. PlantStream’s software is aimed at innovating the ways designers in the oil and gas industry can draft their piping designs, and it already has a proven track record of success.

- Tornincasa, S, Di Monaco,F (Sept, 2010). “The future and evolution of CAD.” Retrieved from the 14th International Research/Expert Conference ”Trends in the Development of Machinery and Associated Technology” TMT 2010, Mediterranean Cruise, 11–18 September 2010.

- Agarwal, A, Chandrasekaran, S, Sridhar,M (June, 2016). “Imagining construction’s digital future.” Retrieved from McKinsey.

- Becker, R (Aug. 2021). “Computer-Aided Design.” Retrieved from Technopedia.

- Tornincasa, S, Di Monaco,F.

- Tornincasa, S, Di Monaco,F.

- Jadhav, S, Kumar, N, Mali, V.(April, 2020). “Autonomous Geometry Processing Using Machine Learning and Forge.”Retrieved from Medium.

- PlantStream (Sep, 2021). ‘Using PlantStream with no previous CAD Experience.’ Retrieved from Plantstream.Medium.com.

- IbisWorld (Feb, 2021). ‘Global Oil & Gas Exploration & Production — Market Size 2005–2027.’ Retrieved from Ibisworld.com.

- Stocker, M, Baffes, J, Vorisek, D (Jan, 2018). “What triggered the oil price plunge of 2014–2016 and why it failed to deliver an economic impetus in eight charts.” Retrieved from WorkBank.org.

- PlantStream (Sep, 2021).

- PlantStream (Sep, 2021).

- Wei, J. et al (April, 2019). ‘Digital innovation, creating the utility of the future.’ Retrieved from Deloitte.com.

Want to Learn More about PlantStream?

Book a Demo Today

Connect with an expert to start your PlantStream journey.

Realize more efficient 3D plant design through seamless workflows.