Chiyoda Corporation is a global EPC contractor with proven experience in large-scale facilities such as oil refineries and natural gas liquefaction plants.

Tadashi Kubo from Electrical System & Smart Grid Engineering Department, and Makoto Kabesu from Control System Engineering Department of Chiyoda talked about their thoughts on our revolutionary new plant design software.

Use Case of Electrical System & Smart Grid Engineering Department and Control System Engineering Department at EPC Company

Chiyoda (Kubo): For decades, the process was a very manual one, and we measured everything by hand. We used to lay string across the design plans to measure the length of objects like racks, and then compare the length of that string according to the scale of the plans. Even now, while the process has been mostly digitized and our design plans are mostly in PDF form, it’s still common to draw a line across the PDF to measure the length of trays.

Chiyoda (Kubo): Yes, we did that for many years. But that was quite a long time ago. (Laughs) However, whether we’re using string or drawing a line across a PDF / 2D design made in CAD, the process is essentially the same.

One of the major problems with doing things that way is that the measurement of each individual line gets saved as an image in PDF format, but the length and object data itself doesn’t get saved anywhere. And since the measurement for an object gets saved on PDFs, this leads to countless PDFs that need to be referenced. It’s not exactly optimal.

Chiyoda (Kabesu): Not only does it impact the overall accuracy of the measurements, but sometimes a certain section might be measured incorrectly. All of the lengths are compiled and exported to a spreadsheet, and any mistake can throw the calculations way off.

Another issue that comes up when there’s no data is that the person who took the measurements of an object is the only one who knows those measurements. It can lead to certain aspects of the project being much less transparent. It’s common that when a person leaves a project, the information goes with them.

When using PlantStream, the trays and cables are all represented digitally and can be measured then and there. It’s easy to save the data for each individual measurement, which leads to greater overall transparency for the project.

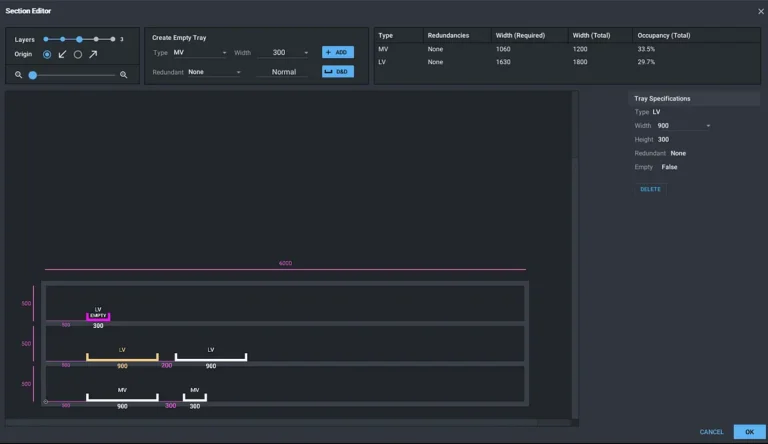

Chiyoda (Kabesu): I think you’re right about that. Unlike pipe routing, 3D CAD tools weren’t used much in the fields of cable routing since we haven’t been able to find the right solution. For example, there’s another software out there that’s able to create cable trays and route electrical cables, but it requires determining the size of the trays before routing the cables. But this is the opposite order from how professionals in the field do things. Usually, the cables get drawn first, and the size and number of cable trays is then determined based on the thickness of the lines. With PlantStream, we can set the number of cables and how thick they are first, and then the information needed for the cable trays is calculated automatically, so it meets our needs much better. Once people in our departments began to understand the different possible applications of PlantStream, it generated a lot of excitement from people looking to improve their workflow.

Chiyoda (Kubo): It has definitely affected the electrical engineering side of things, as a lot of the design work in the field was done manually, and most of us are used to doing all of the planning and design on paper. But it was surprising to see just how easy it was to use PlantStream to do those same tasks. Thanks to its rule-based approach to design, PlantStream is likely to make the transition from manual design methods to a more data-centric approach much smoother.

Something else that PlantStream makes possible is the ability to make quick changes to the design as they come up. For example, I was using the software to design a plot plan and route the cables for a hydrogen plant. However, it was later decided that the location for the electrical substation had to be moved to somewhere completely different. This would usually mean having to redo the plot plan and routing from scratch. But by loading the data of the start and end points of the cabling, I was able to remake the plot plan quickly and easily. The ability to remake plot plans on the fly like this makes incorporating sudden changes incredibly convenient.

Chiyoda (Kabesu): It has a lot of potential for getting younger engineers working on projects much faster. We have a specific methodology across our departments that new engineers have to follow when they first begin working with us, and they usually follow along in our manual as they go through their first designs. But since PlantStream is so easy to use and resembles our department’s methodology so closely, they can get accustomed to the design process quickly. It’s also hard for a newer engineer to look at a 2D design and imagine, for example, what a cable tray would look like in the field, but PlantStream’s visualization makes it so much easier for a newer engineer to conceptualize. So even an engineer that has no field experience can start to build confidence in their design abilities right from the start, and we think that it has a lot of potential as a training tool.

Chiyoda (Kabesu): As we mentioned, PlantStream has a wide variety of uses in our field that extend beyond its design functions. Using it for training is a major one. One piece of advice we have is that there’s no need to build an entire plant from the ground up, so to speak. With PlantStream, it’s easy for us to conduct cable routing without waiting on specifications from other departments, which gives us a real sense of freedom.

Connect with an expert to start your PlantStream journey.

Realize more efficient 3D plant design through seamless workflows.

Subscribe to

Our Newsletter

PlantStream Inc.

Tel:+81-3-6222-8808

Address : 3rd Floor, KDX Hamamatsucho Building,

2-7-19, Hamamatsucho, Minato-ku, Tokyo,

105-0013, Japan

Privacy Policy | Copyright © PlantStream Inc. All Rights Reserved