Chiyoda Corporation, a global EPC contractor with a proven track record in large-scale facilities such as oil refineries and natural gas liquefaction plants, has effectively utilized PlantStream.

Although PlantStream is known for its strengths in the initial design stages, Chiyoda Corporation has successfully leveraged its automatic routing feature even in the final phase of detailed steam trace design with significant work efficiency improvement.

We interviewed Yoh Nagahara and Taito Nanjo from the Piping Engineering Department to learn about the challenges of steam trace design, the background of using PlantStream, and its effects.

Achieving Significant Work Efficiency: First Runner to use PlantStream for EPC Piping Design

Use Case of Piping Engineering Department at EPC Company in EPC Phase

Nagahara: I joined Chiyoda Corporation in 2008 and have been in the Piping Engineering Design Department (formerly the Spatial Design Department). In addition to Engineering work, I have been involved in project operations, including design at the headquarters, working at engineering offices abroad, and being stationed at domestic and overseas construction sites. I have worked on various plant designs, including LNG projects, petrochemical projects, and modular projects. Additionally, I have engaged as a project engineer for plant warranty work, including shutdown brownfield construction.

Nanjo: I have been in the Piping Engineering Department since I joined Chiyoda Corporation in 2019. After two years of on-site training and rotations in piping materials and analysis Gr., I have been involved in design work for LNG projects since my third year.

Nagahara: In the Piping Engineering Department, improving work efficiency is one of the major tasks.

Previously, we invested a lot of man-hours in design by manual work, but now we are transitioning to more efficient design methods through process improvements and the introduction of 3D design technologies.

The aging of experienced designers is a challenge for the entire engineering industry, making it urgent to develop young designers while executing projects. Thus, we are promoting the use of PlantStream to establish it as a new design method.

Nanjo: Our department is actively promoting DX (digital transformation), utilizing various software and tools to improve work efficiency. PlantStream is one of the solutions we are most willing about. The piping layout is time-consuming and requires years of experience, but by using PlantStream, even young designers can learn piping design and contribute to project execution. We believe PlantStream can fundamentally change the way we train designers.

Nagahara: In the Piping Engineering Department, over 90% of the members, from juniors to seniors, have undergone PlantStream training and obtained basic operations. PlantStream is very intuitive and easy to use, even for those who have never touched 3D CAD before.

Nagahara: Unlike process piping, which sets the overall framework of the plant design, steam trace piping (※1) layout is determined in the final phase of detailed design. Due to the huge number of lead and tailpipes, as well as manifolds(※2), these components often weren’t fully designed in the engineering office. It was used to conduct the detailed design at the site office during the construction phase. This meant that design and material quantities are based on estimation until the last minute of the design phase, resulting in on-site design work and in case of additional procurement work.

Recently, to reduce design work at the site and share design information with construction companies in advance, some designs have been conducted on a 2D drawing basis. However, creating a 3D model is challenging due to the extensive design time required.

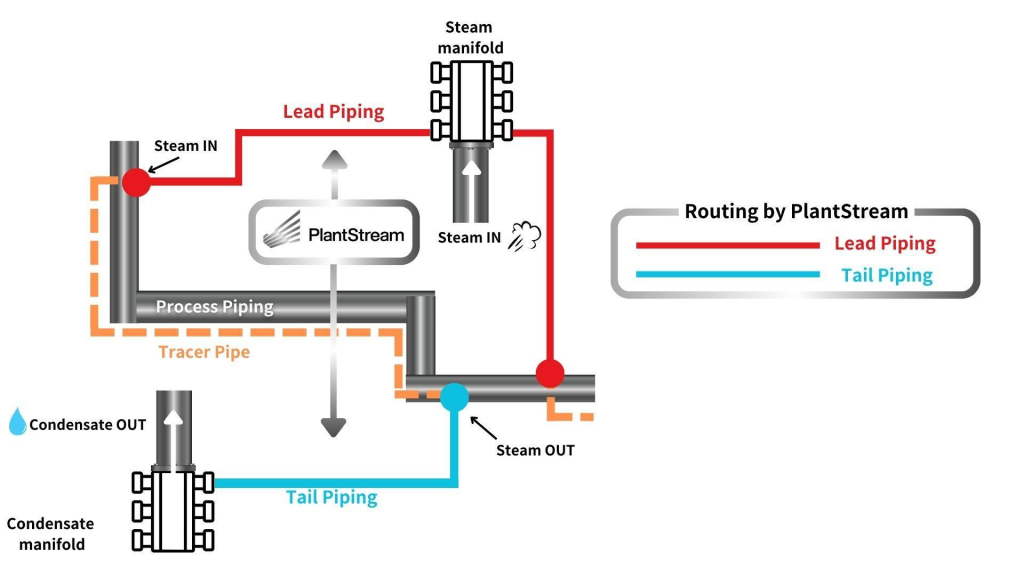

※1 Steam Trace Piping: A system that uses steam to heat pipes and equipment, aimed at preventing freezing, maintaining viscosity, and ensuring process stability. It consists of three main elements:

※2 Manifold: A device installed along the lead or tail piping that controls and manages the supply of steam in lead piping and the discharge of steam and condensate in tail piping.

Nagahara: We had used PlantStream during the basic design stages such as FEED, but we hadn’t applied it on EPC projects (detail design Phase). However, we decided to utilize PlantStream for steam trace design, where we had previously faced challenges.

Steam trace piping doesn’t require special process design requirements; it mainly needs to flow in the direction of free-drain and ensure the trace piping length limitations. However, the number of lines involved in the Steam trace design are about 2,000, and this has led to the decision to apply PlantStream’s auto-routing feature. We determined that PlantStream could significantly enhance design accuracy through 3D modeling, shorten the design period through improved efficiency, and reduce the risk of construction delays and cost increases due to on-site design work.

Nagahara: For this steam trace design work, we formed a team of about ten young engineer members. Each team member was responsible for a specific area and respectively designed approximately 2,000 lead and tail pipes.

The lead and tail piping design starts after the design of the main line to be traced had been completed. To ensure efficiency, we initiated the modeling work in PlantStream for each area as soon as the main line design was finished. This approach allowed each team member to start their assigned section promptly, ensuring a smooth and organized workflow.

Nagahara: Using PlantStream in the detailed design phase allowed us to improve work efficiency significantly.

For this scale of the project, it would take around 2 months for the steam trace lead and tail design utilizing 2D drawing. Instead, we completed the design work in two weeks by utilizing PlantStream, resulting in an approximately 80% reduction in the design duration. Given the huge number of pipes (about 2,000) and the large volume of work, the impact was substantial. We were able to proceed quickly even with a large volume of activity.

While the process area are more complex than the main pipe rack area, the progress of the work was much faster, providing significant benefits, even the auto-routing provided by PlantStream had been gone through a quality check.

Nagahara: Modeling in 3D allowed us to detect and correct errors during the design phase rather than during the on-site construction phase. For example, we used to notice missing lead or tail pipes connecting the manifold and the tracing pipe when construction started. However, with 3D visualization using PlantStream, we could visually check and identify that the lead and tailpipes had a one-to-one relationship with the tracing pipes from their start and end points, significantly improving design quality.

Additionally, PlantStream’s MTO (Material Take Off) function enabled us to accurately determine the material quantities during the design phase, avoiding unnecessary material procurement work.

Nanjo: We typically purchase extra materials, but with PlantStream providing the exact material quantities at the end, we can have confidence that “We have enough material” ensuring we don’t face material shortages later. This allows us to manage materials and construction more smoothly, showcasing PlantStream’s significant contribution.

Nagahara: Using PlantStream for this design work has been a valuable experience for our young engineer. Recently they do not have enought opportunities to engage in actual layout design, so involvement in this experience was a great opportunity and contributed to their growth. I believe this experience will enable them to review isometric drawings with a more advanced perspective in the future.

Nanjo: In this project, as in the design of small-bore piping, we considered access requirements and support of pipes, which will be one of basis for future piping design projects.

Personally, working on the steam trace design was a learning for me. There were issues like manifolds or lead/tail pipes blocking access or the support were not properly design for multiple lead/tail pipes. However, by using PlantStream’s to input in 3D model enable to grasp the space three-dimensionally, and I was able to understand the appropriate layout intuitively.

Using PlantStream lead us to view the design from a new perspective, and this experience can be applied to other projects. I truly felt the strengths of PlantStream in creating 3D design simple and effective.

Nagahara: Subcontractors and on-site supervisors will use the models created with PlantStream during construction. Previously, they had to struggle with GA (General Arrangement) drawings, trying to figure out where the lead/tail pipes would go. However, with the 3D visualization provided by PlantStream, the design has become much clearer and easier to understand compared to before. This will lead to overall improvements in project efficiency.

Nanjo: Beyond steam trace design, we believe that any projects with similar characteristics—simple process requirement and a large number of lines—will benefit greatly from PlantStream. Therefore, we are planning to explore its use in other EPC projects.

Specifically, utility station systems such as steam, air, nitrogen, and water involve a large number of lines. We believe that by continuing to use PlantStream, we can achieve significant efficiency improvements in these areas as well.

Nagahara: For future steam trace designs, we believe that PlantStream can be established as a standard method. The success of using PlantStream in this EPC project has generated many of internal attention, changing the perception that “PlantStream is only for initial design” to demonstrating that it can be effectively used in detailed design phase as well. Rather than fitting PlantStream into existing workflows, we aim to understand its features and use the tool to reform and innovate engineering process.

Connect with an expert to start your PlantStream journey.

Realize more efficient 3D plant design through seamless workflows.

Subscribe to

Our Newsletter

PlantStream

Tel:+81-3-6222-8808

Address : 3rd Floor, KDX Hamamatsucho Building,

2-7-19, Hamamatsucho, Minato-ku, Tokyo,

105-0013, Japan