2024/2/28

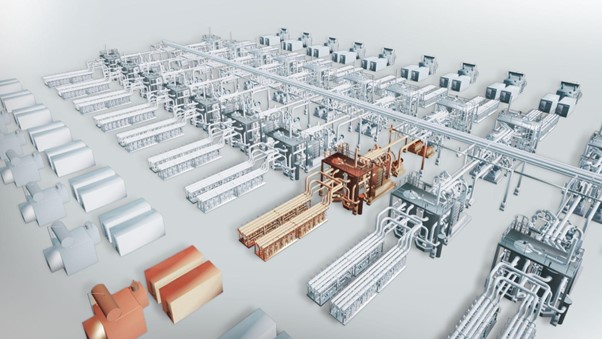

*The 3D model of the large-scale water electrolysis system designed with PlantStream®

We are delighted to announce that our automated 3D CAD software, “PlantStream®,” developed and offered by PlantStream Inc., was utilized for the 3D model design of a large-scale water electrolysis system development project jointly announced by Chiyoda Corporation and Toyota Motor Corporation (hereinafter referred to as “Toyota”).

Regarding the details of the joint development of the large-scale water electrolysis system, you can find it in the introduction video produced by Chiyoda Corporation, where PlantStream is introduced as the 3D model creation tool.

Video link: https://www.youtube.com/watch?v=QQi1yjPsqwc

*This video is being showcased at the H2&FC EXPO held at Tokyo Big Sight from February 28th to March 1st, 2024.

This case illustrates how PlantStream® can be utilized to meet the increasing demands of the rapidly expanding hydrogen production market, enabling the creation of highly accurate 3D model designs in significantly shorter timeframes compared to traditional methods.

Moving forward, we remain committed to provide rapid and efficient 3D design to solve challenges through providing PlantStream®, aiming to revolutionize plant design in the industry.

Mr. Kouichi Saba, Assistant PM of the Project GX Collaborative Innovation Department at Chiyoda Corporation (left), and Mr. Takanori Koyama, PM (right).

Comment from Mr. Takanori Koyama, PM of the Project GX Collaborative Innovation Department at Chiyoda Corporation:

In the initial phases of large-scale water electrolysis systems and dehydrogenation plants projects, where there are few actual EPC projects and various considerations are required, PlantStream® can be highly effective for flexible and rapid layout studies as well as optimization of layouts through 3D models. We feel that the ability to accurately estimate EPC costs in the early stages is the greatest benefit, and this has been highly praised by Toyota.

As a EPC contractor, being able to select the optimal design from various perspectives such as material quantity, equipment safety, and maintenance, and being able to grasp issues that could not be studied in 2D, while sharing images through 3D models with customers, are also significant advantages.

Comment from Seitaro Narue, Director and CEO of PlantStream:

In the design of large-scale water electrolysis systems, PlantStream® has contributed to minimizing the footprint of equipment, by considering maintainability and transportability, resulting in cost reduction. We are pleased that the strength of PlantStream®, which enables 3D model creation and layout study in the early phases, has been demonstrated.

About PlantStream®:

PlantStream® is an automated 3D CAD software developed by combining the expertise of Chiyoda Corporation, a leading company in the plant engineering industry, and Arent Inc., a startup specialized in 3D CAD development.

PlantStreamt® has a powerful auto routing feature for spatial design in plant engineering. Leveraging industry-leading design expertise, the auto-routing function has revolutionized the conventional design work flow, reducing the time required for design, allowing around 1,000 pipes to be automatically designed in just 1 minute, instead of the 2 hours it previously took to design each pipe. This enables up to 75% reduction in initial spatial design work.

In addition to that PlantStream®’s equipment template features enable the effortless creation of highly precise 3D models comparable to models by skilled plant engineers through simple operations such as drag-and-drop and parameter adjustment.

Moreover, the auto-routing feature enable easy rerouting of pipelines, allowing for the quick creation of multiple layouts. As a result, it is a characteristic feature of PlantStream® that users can create multiple layouts easily and quickly, while considering various perspectives such as material quantity, safety, and maintenance, enabling selection of the optimal layout and design quality improvement from the initial design stage.

Currently, PlantStream® has been adopted by over 30 EPC contractors and plant owners, both domestic and international.

Our mission at PlantStream is to “Revolutionize Plant Design, Boost Creativity,” and we are dedicated to addressing the challenges faced by the global plant industry. If you face problems and concerns with plant engineering efficiency, please feel free to contact us.

Subscribe to

Our Newsletter

PlantStream Inc.

Tel:+81-3-6222-8808

Address : 3rd Floor, KDX Hamamatsucho Building,

2-7-19, Hamamatsucho, Minato-ku, Tokyo,

105-0013, Japan

Privacy Policy | Copyright © PlantStream Inc. All Rights Reserved