PlantStreamのお役立ち情報

Why PlantStream is becoming a game-changer in oil and gas

Date :Aug 1, 2022

PlantStream offers a unique product that fills a gap in the market for oil and gas companies, but how did it get here? We take a look at the history and attributes of PlantStream’s technology, and how it can help the oil and gas industry.

PlantStream CEO, Seitaro Narue

Go Digital Energy — 6th Annual Conference

Companies in the oil and gas industry are dealing with an increasing number of economic challenges, especially as the COVID-19 pandemic continues to have an impact.

There’s more pressure than ever to decarbonize as climate change worsens — some countries, like Denmark, are canceling licenses and permits for gas exploration that would eventually halt oil and gas production in areas. Consumers are also making different choices, demanding cleaner options like wind and solar power from their energy providers.

Digital transformation — where data, technology, software, and automation are used to transform systems, processes, and workflow across organizational structures — can be a smart and inexpensive way for oil and gas companies to lower their production costs and become more efficient. Computer-aided design (CAD) is one tool in a digital transformation strategy — and this is where PlantStream comes in¹.

PlantStream aims to fill a gap in the industry

The design and production phase of piping in an oil or gas company can be a long and complicated process — and as time is money, it can also be costly. Add to this greater financial pressure and the need to cut costs², and PlantStream spotted a gap.

As Seitaro Narue, CEO of PlantStream and Hiroki Kamobayashi, CEO of autonomous CAD software company, Arent explained in an interview in early 2021, the idea of using artificial intelligence to design piping had been popular since the mid-2010s. But PlantStream wanted to go a step further to be more specific than merely offering algorithms.

The two CEOs wanted to create a ‘specialized CAD system’ that could be highly technical, but also user-friendly, so that engineers could more accurately, quickly, and cost-effectively create a blueprint³. Oil and gas plants are incredibly complex, and PlantStream aims to revolutionize existing workflows that plant engineers are already using.

Since the company’s first product release in September 2020, PlantStream engineers have worked closely with partners to iron out kinks in the software and find ways to make it even more valuable. In April 2021, PlantStream came out of beta mode and is now capable of automatically routing 1,000 pipes in just 60 seconds. And that’s not all PlantStream has to offer.

PlantStream’s unique CAD attributes

CAD refers to the use of computers and algorithms to help designers draft blueprints more accurately, and has been around for decades — from crude 2D wire-like models, to 3D shapes with curves and depth, to software that incorporates smart data into the 3D models.

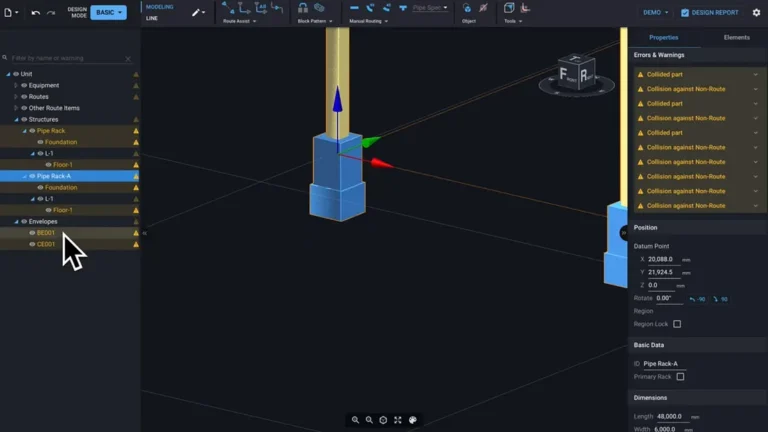

PlantStream’s autonomous CAD software is based on something called block pattern, a pre-set template of equipment and peripheral piping layout. That stands out from manual 3D CAD design options on the market, because simply by changing parameters within the software, designers can intuitively edit 3D models in a much shorter amount of time — seconds rather than minutes.

PlantStream software includes drag-and-drop features that make it user-friendly and easy for a designer to develop a sophisticated design more quickly. The software also offers some teaching, by showing the user how to build a model more effectively, and features pop-ups that explain errors.

PlantStream users are also able to see a shape in full form within the software, and even rotate it to see different edges and curves. This is key for oil and gas companies looking to design advanced piping with limited time and budget. By modeling thousands of pipes in just minutes, companies can greatly reduce the time they need to plan and construct piping design, and avoid some expensive construction errors.

PlantStream has already seen some success

One of PlantStream’s earliest users was Chiyoda Corporation. Chiyoda tested out PlantStream’s 3D software while the company was still trying to troubleshoot errors⁴ and reported that the software was successful in streamlining their production process.

According to the design team at Chiyoda, they felt held back by cumbersome 2D designs, which were not specific enough for their clients. With PlantStream’s advanced 3D CAD, they were able to create better models and get better feedback from their clients earlier on in the design process.

The future of the industry and where PlantStream fits in

The oil and gas industry will not look the same a decade from now. There’s an increasing number of requirements by state and federal governments to reduce carbon emissions, which means major companies are already having to reconsider how their energy mixes are accomplishing their goals and meeting sustainability requirements.

Many oil and gas companies are looking toward digital transformation to save money and make their production more efficient. That includes everything from investing in 5G technology, automation, and cloud computing, to using tools that have been around for a while, like CAD. PlantStream’s 3D autonomous CAD is a game-changer for oil and gas companies looking to shave off budgetary constraints in the design, planning, and construction phase of piping. With proven success and a team of highly advanced engineers, PlantStream offers a tool that is unlike many others on the market, and could help oil and gas companies stay relevant in a changing industry.

- McKinsey (March 2021). “The big choices for oil and gas in navigating the energy transition.” Retrieved from Mckinsey.com.

- Krauskopf,L,Resnick-Ault,J (Dec. 2019). “U.S. energy shareholders seek to leave behind a lost decade.” Retrieved from reuters.com.

- PlantStream (Feb. 2021) “We’re in the same boat.” Disrupting the plant engineering industry.” Retrieved from PlantStream.medium.com.

- PlantStream (Sep 2021). ‘Using PlantStream with no previous CAD Experience.’ Retrieved from Plantstream.Medium.com.